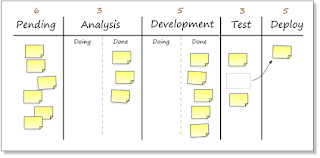

KANBAN - Upstream Downstream and WiP

Economists speak of supply and demand, scarcity of resources etc. In this grand scheme of things, the overarching influence of capitalistic tendencies, an individual is more often than not a means to an end. Then there is the constant effort from people who tries to earn a decent living, improve living standards etc. And on top of it all, the altruistic heart that wants to contribute towards society and give something back. Any effort required is constrained by time and energy. One of the smart ways of dealing with this limited capacity, is use of scheduling techniques like KANBAN. Kanban (看板?) (literally signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing.Kanban is an inventory-control system to control the supply chain. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. Kanban is one method to achieve JIT The book by the same name authored by David J Anderson,...